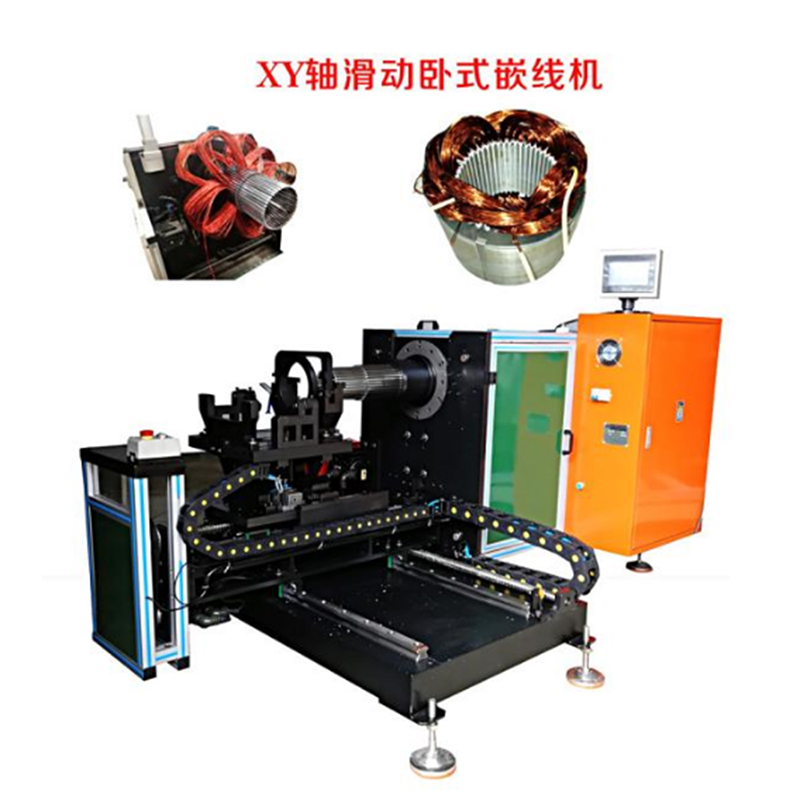

Horizontal Stator Coil Inserting Machine

Powered by an industrial programmable PLC, this machine is equipped with a slot wedge and offers a wide range of functions such as automatic fixed-length feeding, cutting, punch forming, and stator embedding together with the coil. With its advanced features and user-friendly interface, this machine is set to revolutionize the manufacturing process of electrical motors.

Designed for Precision and Efficiency

With the Horizontal Fully Automatic Coil Stator Inserting Machine, precise coil embedding has never been easier. The machine allows for easy adjustment of the coil embedding speed, ensuring optimal results for any project. Additionally, different slotting wedge feeding methods can be set according to the requirements of different motors, enhancing its adaptability for various applications. The user will benefit from the machine's high degree of automation, which significantly reduces the need for manual intervention. This, coupled with its wide adaptability and easy operation, makes it the ideal choice for manufacturers seeking efficient and hassle-free production processes.

Advanced Control and Interface

Equipped with a state-of-the-art human-machine control interface, the Horizontal Fully Automatic Coil Stator Inserting Machine offers a highly convenient and user-friendly experience. The interface provides various functions such as status display, fault alarm, and parameter settings, allowing the user to easily monitor and control the machine's operation. This advanced control system optimizes the production process by providing real-time information and facilitating quick decision-making. With the Horizontal Fully Automatic Coil Stator Inserting Machine, manufacturers can expect increased productivity and improved quality control.

Simplified Workflow and Quick Mold Replacement

At our company, we understand the importance of minimizing downtime and maximizing productivity. That's why the Horizontal Fully Automatic Coil Stator Inserting Machine is designed with easy and quick mold replacement in mind. Manufacturers can effortlessly switch between different molds, reducing the time spent on setup and maximizing the machine's operational capacity. With this streamlined workflow, businesses can expect increased efficiency and output, translating into higher profits and customer satisfaction.

In conclusion, the Horizontal Fully Automatic Coil Stator Inserting Machine is a game-changer in the field of automation. With its comprehensive control system, advanced features, and user-friendly interface, it offers unmatched precision, efficiency, and convenience. Whether you are a small-scale manufacturer or a large industrial operation, this machine will undoubtedly elevate your production process to new heights. Experience the future of automation with the Horizontal Fully Automatic Coil Stator Inserting Machine and unlock endless possibilities in the world of electrical motor manufacturing.

Features

1.Wide range of application, high degree of automation, easy operation, convenient and fast mold replacement

2.Configure man-machine interface, with status display, fault alarm, all kinds of parameter Settings and other functions.

3.The inserting speed can be set in sections, and different feeding wedge modes can be set according to different motors

Application

Parameters

| Model | DLM-5 |

| Stack Height | 80~300mm |

| StatorI.D | φ70- φ250mm |

| Stator O.D | ≤φ300mm |

| Heihgt of Edge Folded | 2-4mm/4-7mm |

| Insulation Paper's Thickness | 0.188~0.35mm |

| Efficiency | ≈ 1.5s/s |

| Power Supply | 380V/50/60Hz 3.5KW |

| Weight | ≈600Kg |

| Dimension | (L)1600x(W)1420x(H)1600mm |

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

3.What is the average lead time?

For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with

your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

4.What kinds of payment methods do you accept?

You can make the payment to our bank account or L/C AT SIGHT:

30% deposit in advance, 70% paid before delivery.