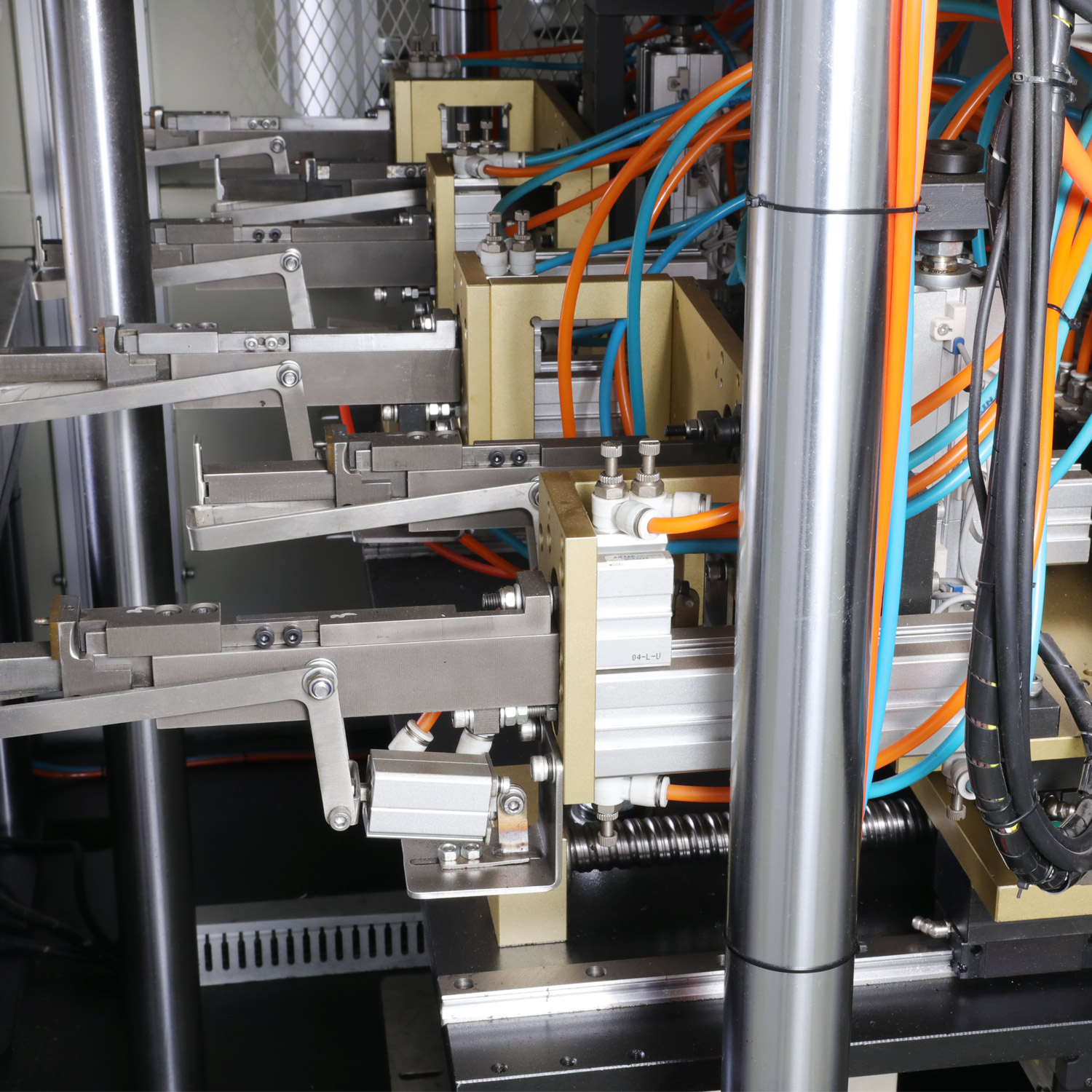

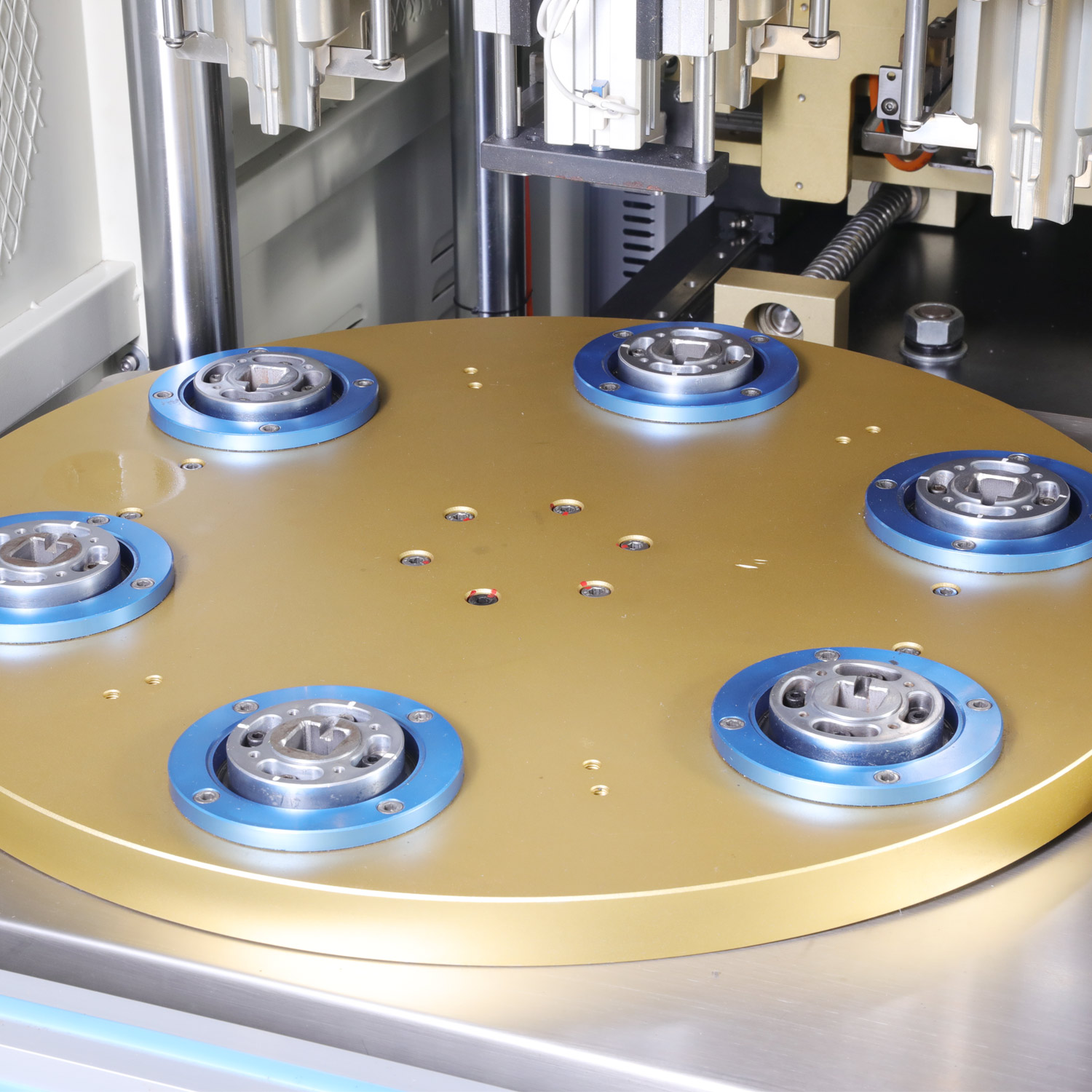

6 Heads 12 Working Stations Coil Winding Machine

This winding machine is equipped with innovative features that guarantee excellent performance. The stator winding is carried out seamlessly, and the winding method automatically skips sections, repairs lines, and indexes in one step. Process parameters can be easily set via the user-friendly human-machine interface, providing maximum convenience and flexibility. Additionally, the winding tension is fully adjustable for optimal control and customization according to specific requirements.

One of the standout features of this machine is its automatic segmentation feature. This feature ensures that the winding process jumps easily to the next segment, eliminating any potential errors or inconsistencies. In addition, the automatic wire trimming function can accurately trim excess wire without manual intervention, saving valuable time and energy.

Efficiency is a key aspect of this advanced winding machine. It offers single-step and continuous winding capabilities to meet a wide range of production needs and preferences. The resulting coil embedding is always impeccable, guaranteeing top quality for every coil produced. With its high working efficiency, this machine significantly increases productivity levels, making it an indispensable asset in any coil manufacturing operation.

This winding machine offers convenience and reliability in maintenance and troubleshooting. With its automatic fault detection and alerting capabilities, any potential issues are immediately identified so they can be resolved quickly and minimize downtime. The user-friendly human-machine interface also helps diagnose problems and optimize performance. Additionally, the machine’s design prioritizes ease of maintenance, ensuring that any necessary repairs or adjustments can be made seamlessly without disrupting production schedules.

All in all, the six-head, twelve-station vertical winding machine is a cutting-edge solution for the coil winding process. Its automatic winding function combined with functions such as segment skipping, thread trimming and fault detection ensures excellent performance and reliability. This machine has adjustable winding tension and high working efficiency, which is very suitable for various production requirements. Investing in this advanced equipment will undoubtedly streamline coil winding operations, maximize productivity and deliver superior results.

Features

1. Stator winding seamless, winding mode automatically jump, repair, index one step complete

2. The automatic wire cutting function can accurately trim excess wire without manual intervention, saving valuable time and energy

3. With its automatic fault detection and alarm function, any potential problems can be identified immediately for quick resolution and to minimize downtime.

Application

Parameters

| Model | 6 heads 12 working stations coil winding machine |

| Suitable stack height | 15-70mm |

| Wire diameter range | 0.12-0.8mm |

| Ma.Winding speed | 1500-3000 |

| Suitable motor poles | 2、4、6、8 |

| Air Pressure | 0.5-0.7MPA |

| Power Supply | 380V 50/60Hz |

| Power | 10Kw |

| Weight | 3500Kg |

| Dimension(LxWxH) | 1800*1600*2200mm |

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

3.What is the average lead time?

For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when

(1) we have received your deposit, and

(2) we have your final approval for your products. If our lead times do not work with

your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

4.What kinds of payment methods do you accept?

You can make the payment to our bank account: 40% deposit in advance, 60% paid before delivery.