Introduction

In the rapidly evolving landscape of electrical engineering, motor winding plays a crucial role in ensuring the seamless operation of various devices. With the continuous demand for improved efficiency and precision, the development of stator automatic winding equipment has emerged as a game-changer in the production industry. This blog will delve into the benefits and advancements of this technology, which has revolutionized the industry with its ability to streamline the production process and deliver high-quality results.

Streamlining the Production Process:

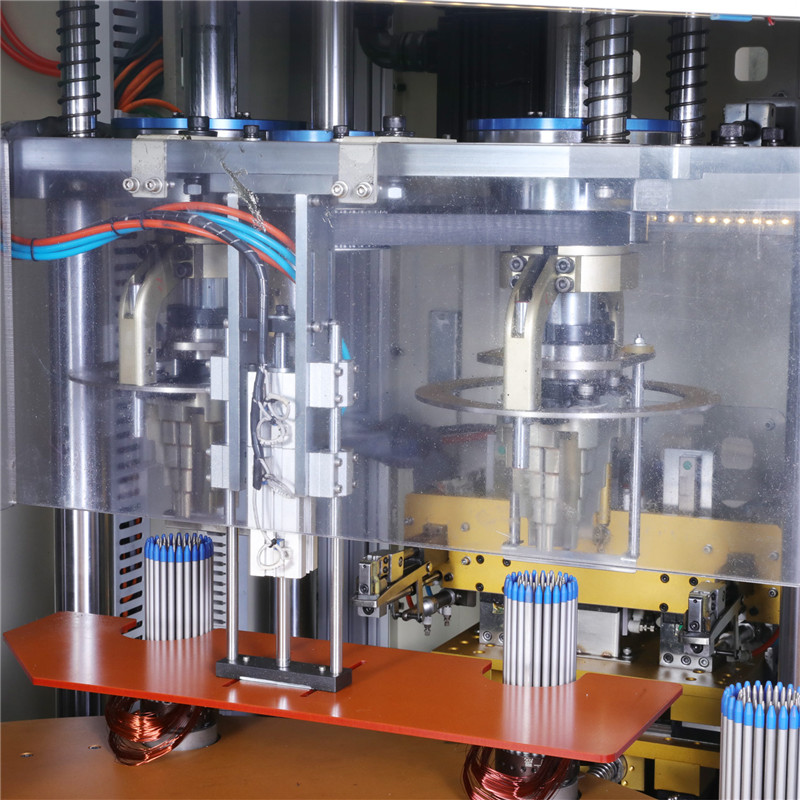

Stator automatic winding equipment has been designed to automate the winding process, reducing manual labor and significantly increasing production efficiency. By employing cutting-edge technology and intelligent systems, these equipment eliminate the need for time-consuming and error-prone manual winding. This not only saves time but also minimizes the risk of human errors, ensuring product consistency and reliability.

Improved Precision and Quality:

One of the key advantages of stator automatic winding equipment is its ability to achieve a higher level of precision and quality in the winding process. These machines are equipped with advanced control systems that enable highly accurate wire positioning and tension control. As a result, the winding pattern is consistent and uniform, reducing the likelihood of defects and improving the overall quality of the stator windings.

Increased Output Capacity:

With the demand for electrical products constantly on the rise, manufacturers are constantly seeking ways to increase their production capacity. Stator automatic winding equipment has proven to be an invaluable asset in this regard. By automating the winding process, these machines significantly reduce the time required to wind a stator, thereby increasing the overall output capacity of the production line. This enhanced productivity allows manufacturers to meet the market demand while maintaining high-quality standards.

Energy Efficiency and Cost Reduction:

Stator automatic winding equipment also provides energy-efficient solutions for the production industry. The automation of the winding process ensures optimal wire usage, reducing material waste and lowering production costs. Additionally, the precise control of wire tension prevents coil deformation and reduces the risk of insulation damage. These factors contribute to an overall reduction in operational costs and a greener approach to manufacturing.

Flexibility and Adaptability:

In today's rapidly changing market, adaptability is a key factor for successful production lines. Stator automatic winding equipment offers a high degree of flexibility, allowing manufacturers to easily switch between different winding configurations and adapt to evolving market needs. By minimizing changeover time and simplifying the reprogramming process, these machines enable manufacturers to quickly respond to customer demands, enhancing their competitiveness in the market.

Conclusion:

Stator automatic winding equipment has revolutionized the motor winding industry by combining efficiency, precision, and flexibility. Through the implementation of intelligent control systems and automation, these machines offer numerous benefits such as streamlined production processes, improved quality and precision, increased output capacity, energy efficiency, and flexibility. Manufacturers who embrace this advanced technology can gain a competitive edge by delivering high-quality products efficiently and cost-effectively. As we move forward in the digital age, the stator automatic winding equipment will continue to play an integral role in shaping the future of electrical engineering.

Post time: Aug-30-2023