Introduction

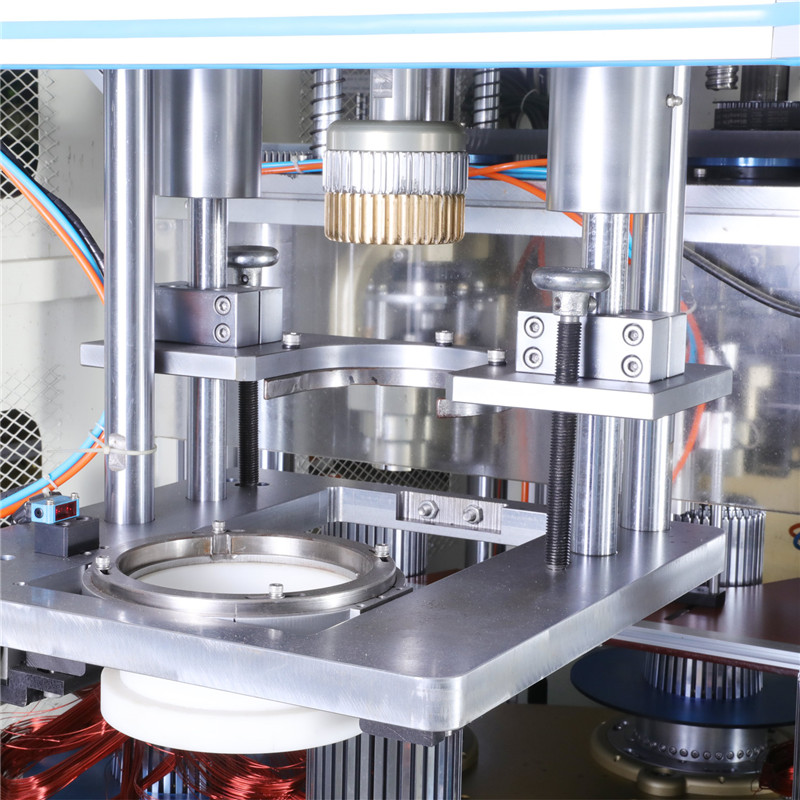

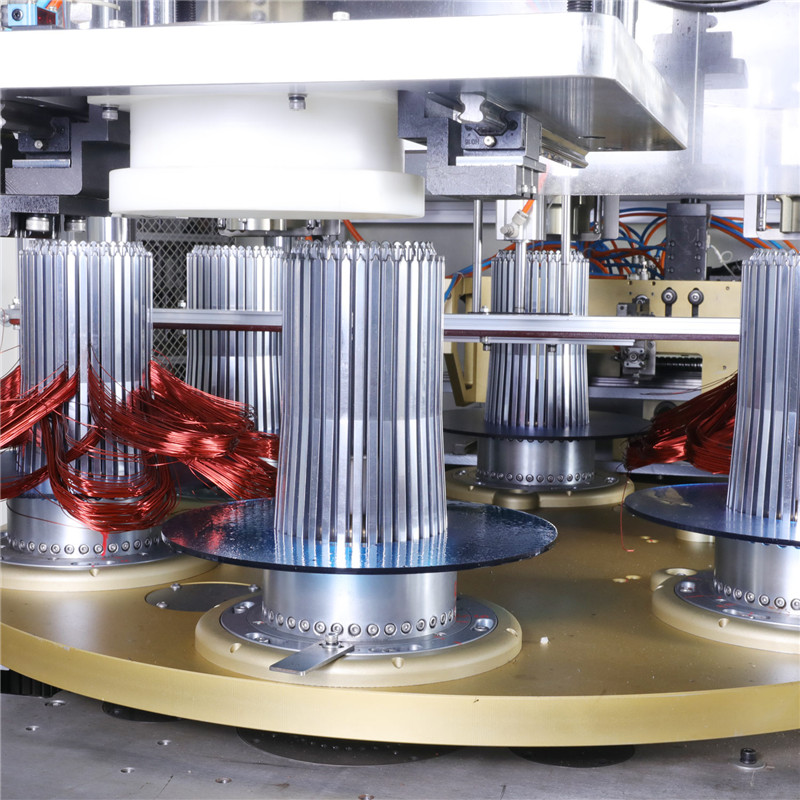

The all-in-one Coil stator Winding and Inserting Machine has gained significant popularity in various industries due to its numerous advantages. With its compact design, high efficiency, and flexibility in installation and operation, this machine is seen as a cost-effective solution for businesses. This article explores the benefits of this machine, the industries it applies to, and the precautions operators should take while using it.

Advantages of the All-in-One Coil stator Winding and Inserting Machine:

One of the key advantages of the all-in-one Coil stator Winding and Inserting Machine is its space-saving feature. By adopting a compact design that minimizes occupied space, this machine allows businesses to make the most of their available installation space. As a result, it proves to be an ideal choice for industries where space is a precious commodity.

Furthermore, the all-in-one Coil stator Winding and Inserting Machine boasts excellent matching performance. Installation of the machine is typically embedded in the user's existing equipment. Therefore, the touch center of the equipment requires a high level of compatibility with the user's original equipment. This ensures that the machine can be seamlessly integrated and used with minimal hassle, ultimately enhancing cost-effectiveness and practicality.

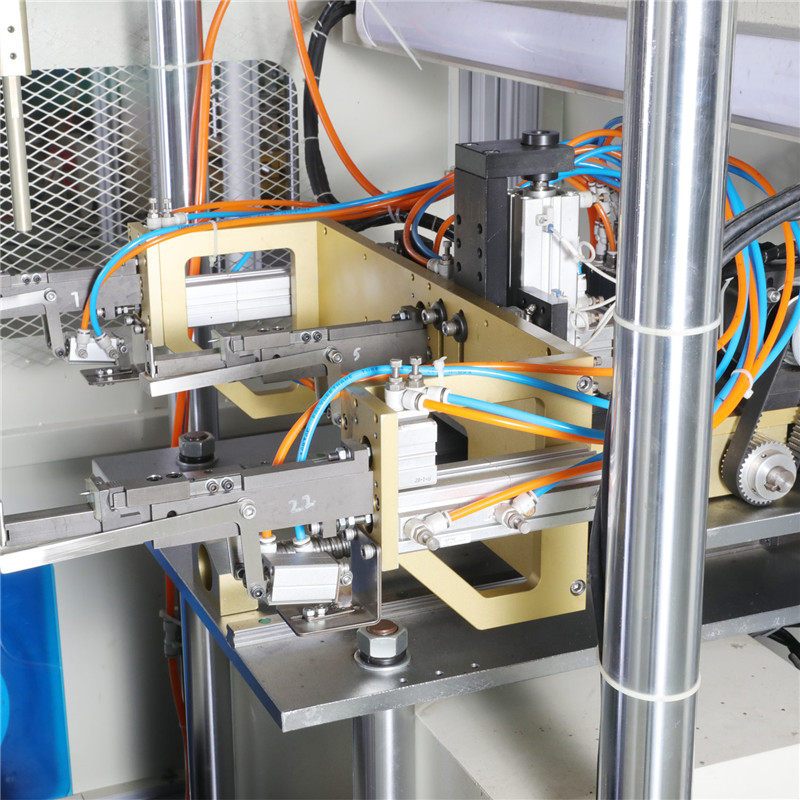

Reliability is another significant advantage of the all-in-one Coil stator Winding and Inserting Machine. During the design process, utmost attention is given to ensure the machine's robustness and durability. Factors such as heat dissipation, dustproof and waterproof design, electromagnetic compatibility, and anti-vibration features are meticulously considered. This results in a highly reliable machine that can withstand demanding working conditions.

Applications in Various Industries:

The all-in-one Coil stator Winding and Inserting Machine finds applications in a wide range of industries due to its versatility. In the manufacturing sector, this machine is commonly used in the production of electrical transformers, motors, and coils. It also finds application in the automotive industry for the production of electric vehicles, where compactness and efficiency are crucial.

Medical equipment manufacturing is another sector where the all-in-one Coil stator Winding and Inserting Machine is widely employed. It assists in the production of medical devices such as pacemakers, defibrillators, and imaging equipment. Additionally, this machine is utilized in the aerospace industry, where it helps in the manufacturing of components for satellites, aircraft, and other aviation-related products.

Precautions for Operation:

To ensure the optimal performance and longevity of the all-in-one Coil stator Winding and Inserting Machine, operators must adhere to certain precautions. Firstly, it is crucial to carry out proper heat dissipation, dustproof, and waterproof measures as specified by the manufacturer. This will safeguard the machine from potential damages caused by excessive heat, dust, or moisture.

Moreover, operators should focus on electromagnetic compatibility design to prevent any interference with other equipment. Additionally, anti-vibration design should be considered to minimize the impact of vibrations on the machine and enhance its stability during operation.

Conclusion:

The all-in-one Coil stator Winding and Inserting Machine offers numerous advantages in terms of space-saving, efficient performance, and reliable operation. Its ability to adapt to various industries, coupled with its compact design and flexibility, makes it a valuable asset for businesses. However, operators should take the necessary precautions to ensure the machine's optimal performance and durability. By leveraging these advantages and adhering to safety measures, businesses can benefit from increased productivity and cost-effectiveness in their operations.

Post time: Aug-30-2023